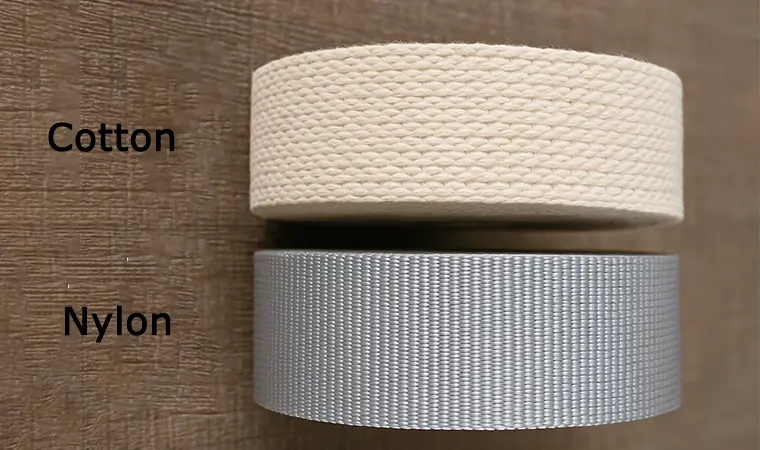

Choosing the right webbing material is one of the most critical decisions in product development. It directly impacts performance, durability, feel, and cost. As a webbing manufacturer with over 20 years of experience, we frequently guide our B2B clients through the "natural vs. synthetic" debate. The two main camps are classic, comfortable cotton and the high-performance synthetics: nylon and polyester.

This guide provides a direct, head-to-head comparison from a manufacturer's perspective. We'll break down the pros and cons of each material to help you make an informed decision that aligns with your product's function and your brand's promise.

Understanding Cotton Webbing: The Natural Choice

Cotton webbing is valued for its soft hand-feel, breathability, and natural, matte appearance. It's an eco-friendly option derived from a renewable resource, which is a significant selling point for sustainable brands. Our cotton webbing is a popular choice for products where comfort and aesthetics are paramount.

- Key Strengths: Softness (ideal for skin contact), biodegradable, holds dye well for rich colors, classic aesthetic.

- Key Weaknesses: Lower tensile strength than synthetics, absorbs moisture (can lead to mildew and stretching when wet), poor UV resistance, and can fray more easily if not cut properly.

- Best Applications: Perfect for apparel and fashion accessories like belts and hoodie drawstrings, handles for tote bags and light luggage, and decorative trims.

For a deeper dive into this material, you can read our dedicated guide to cotton webbing.

The Synthetic Powerhouses: Nylon vs. Polyester

Nylon and polyester are the workhorses of the webbing industry. They offer superior technical performance that natural fibers simply cannot match. While similar, they have distinct properties that make them suitable for different high-demand applications.

Nylon Webbing: Strength and a Smooth Feel

Nylon webbing is known for its exceptional tensile strength and excellent abrasion resistance. It has a smooth, slightly lustrous finish and a small amount of stretch, which allows it to absorb shock from dynamic loads. This makes it a top choice for products that need to be both strong and comfortable, such as high-quality pet collars and leashes.

Polyester Webbing: Durability Against the Elements

Polyester webbing rivals nylon in strength but has one key advantage: extremely low stretch, even when wet. It also boasts superior resistance to UV radiation and water, making it the undisputed champion for outdoor use. It won't degrade or lose strength after prolonged sun exposure, making it ideal for outdoor gear and safety equipment.

Head-to-Head Comparison: Cotton vs. Nylon vs. Polyester

To help you decide, here is a direct comparison of the most important factors for B2B product developers. This is the same framework we use when advising our clients.

| Feature | Cotton Webbing | Nylon Webbing | Polyester Webbing |

|---|---|---|---|

| Strength & Durability | Moderate. Best for light to medium-duty applications. | Excellent. Superior tensile strength and abrasion resistance. | Excellent. Very high tensile strength, similar to nylon. |

| Feel & Comfort (Hand-Feel) | Very soft and breathable. Ideal for direct skin contact. | Smooth and flexible. Comfortable but can be slippery. | Slightly stiffer than nylon but still smooth. |

| Water Resistance | Poor. Absorbs water, weakens, and is prone to mildew. | Good. Dries quickly but loses some strength when wet. | Excellent. Repels water, maintains strength, and resists mildew. |

| UV Resistance | Poor. Fades and degrades with prolonged sun exposure. | Moderate. Can degrade over time with heavy sun exposure. | Excellent. The best choice for outdoor applications. |

| Environmental Impact | Good. Renewable and biodegradable. | Poor. Petroleum-based and not biodegradable. | Poor. Petroleum-based. (Eco-friendly rPET options exist). |

| Best For... | Apparel, fashion bags, eco-conscious brands. | Pet products, lifting slings, military gear, shock absorption. | Cargo tie-downs, safety harnesses, marine and outdoor gear. |

How to Choose the Right Webbing for Your Product

When sourcing webbing, your brand's reputation depends on making the right material choice. Ask yourself these critical questions:

- What is the primary load requirement? For heavy-duty, load-bearing applications like safety harnesses or cargo straps, polyester is the clear winner. For fashion belts, cotton is sufficient.

- Will the product be used outdoors? If the answer is yes, polyester's UV and water resistance make it the only reliable choice to prevent product failure and color fading.

- Is comfort a key selling point? For products like garment trims or straps on high-end bags that touch the skin, the softness of cotton is a significant advantage.

- Does your brand have a sustainability focus? If your brand identity is built on being eco-friendly, cotton or recycled polyester (rPET) are your best options. We discuss this in our guide to sustainable webbing.

Conclusion: The Right Material for the Right Mission

There is no single "best" webbing material—only the most appropriate one for your specific application. Cotton offers a natural feel and eco-credentials for fashion and comfort-focused products. Nylon provides superior strength and a smooth finish for high-wear items. Polyester delivers unmatched durability for outdoor and safety-critical gear.

Understanding these fundamental differences is key to developing a successful product. If you're unsure which material is right for your project, our team is here to help. We leverage our manufacturing expertise to ensure you get the perfect webbing solution that meets your performance, aesthetic, and budget requirements. Contact us today to request samples or get a quote for your next project.