Sourcing webbing for climbing gear, safety harnesses, or cargo straps? The choice between flat and tubular weave is critical for performance and safety. As a specialized manufacturer, TMG Webbing produces both types in high-volume. Whether you need rigid Flat Polyester for tie-downs or flexible Tubular Nylon for climbing slings, we have the looms and expertise to supply your production line.

This guide breaks down the structural differences and helps you specify the right weave for your bulk order.

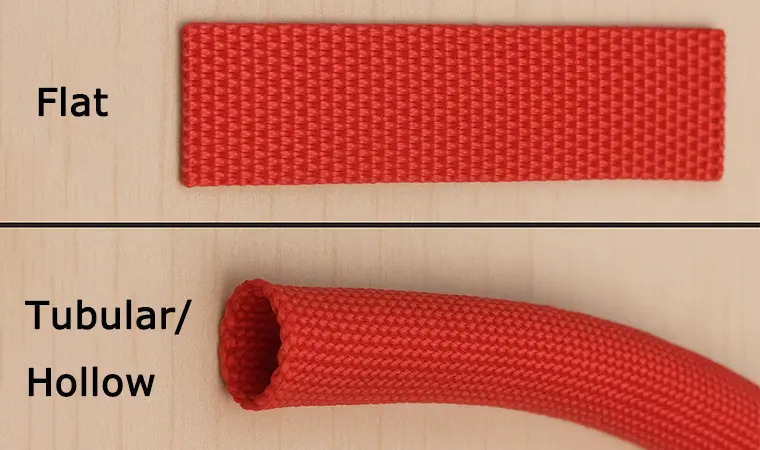

What is Flat Webbing? (Solid Weave)

Flat webbing is the industry workhorse—a solid, single-layer strap. It is designed for high tensile strength and stiffness.

- Best For: Cargo tie-downs, backpack straps, pet leashes.

- Factory Advantage: Our flat webbing is tightly woven to resist bunching in buckles, ideal for automated sewing lines.

- Material: Typically Polyester (for low stretch) or Polypropylene.

What is Tubular Webbing? (Hollow Weave)

Tubular webbing is woven as a tube and flattened. This double-layer construction creates a strap that is thicker, softer, and far more durable against edges.

- Best For: Climbing slings, safety harnesses, parachute static lines.

- Factory Advantage: We produce tubular nylon that passes strict abrasion tests, crucial for life-safety gear.

- Material: Primarily High-Tenacity Nylon 6 or 6.6.

🏭 Need Custom Flat or Tubular Webbing?

We manufacture both weaves to your exact specifications.

- Widths: 10mm to 100mm (Customizable)

- Materials: Nylon, Polyester, PP, Dyneema®

- Test Reports: Tensile Strength & Abrasion Resistance

Flat vs. Tubular: Technical Comparison for Buyers

Use this table to decide which spec to put on your RFQ (Request for Quote):

| Feature | Flat Webbing | Tubular Webbing |

|---|---|---|

| Structure | Solid, single-layer | Hollow, double-layer |

| Abrasion Resistance | Good | Excellent (No exposed edges) |

| Hand Feel | Stiff, rigid | Soft, pliable, easy to knot |

| Cost | Lower (Economical) | Higher (Premium construction) |

| Primary Use | Static Loads (Tie-downs) | Dynamic Loads (Climbing/Safety) |

A Manufacturer’s Recommendation

- Choose Tubular if your product involves knots (like climbing slings) or rubs against rough surfaces. The hollow structure protects the core fibers.

- Choose Flat if you need the strap to feed smoothly through ratchets or buckles without rolling, or if cost is the primary driver.

Still unsure? Send us your product drawing or a sample. Our engineering team will recommend the most cost-effective weave that meets your safety requirements. Get a quick quote from TMG Webbing today.