In the webbing industry, appearance can be deceiving. A high-quality Polyester strap can look identical to Nylon, yet their performance in critical applications differs drastically. Using the wrong material (e.g., using Polypropylene for climbing gear) can lead to catastrophic failure.

While professional labs use mass spectrometry, you don't need million-dollar equipment to verify your incoming raw materials. As a manufacturer, TMG Webbing uses three rapid field tests to verify fiber content. This guide outlines the Water Float Test, the Burn Test, and the Chemical Solvent Test.

Test 1: The Water Float Test (Specific Gravity)

This is the fastest non-destructive way to distinguish Polypropylene (PP) from Nylon or Polyester. It works based on specific gravity (density).

- The Method: Cut a small piece of webbing and submerge it in a glass of water. Press it down to release air bubbles.

- The Result:

- Floats: It is Polypropylene (PP). PP has a specific gravity of ~0.91, which is lighter than water.

- Sinks: It is Nylon (1.14) or Polyester (1.38). Both are denser than water.

Note: If you need to distinguish between Nylon and Polyester, proceed to the Burn Test.

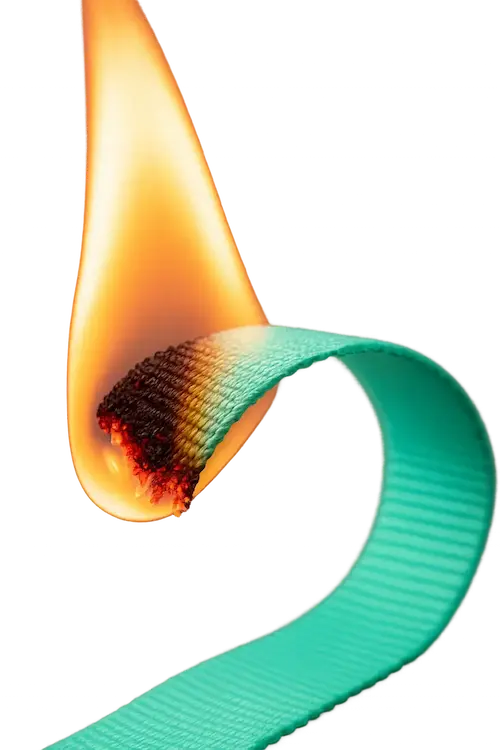

Test 2: The Burn Test (Flame Analysis)

Warning: Perform this test in a well-ventilated area away from flammable materials. Use tweezers.

This is the industry-standard field test. By observing the flame color, smell, and ash residue, you can accurately identify the polymer.

| Material | Smell | Flame Behavior | Residue (Ash) |

|---|---|---|---|

| Nylon | Celery / Seared Vegetable | Blue base flame, melts rapidly | Hard, round, grey/brown bead |

| Polyester | Sweet Chemical / Black Smoke | Yellow flame, black smoke | Hard, round, black bead |

| Polypropylene | Asphalt / Candle Wax | Briefly flares, melts like wax | Hard, tan/brown block |

| Cotton | Burning Paper | Yellow flame, burns fast | Soft, grey powder ash |

Test 3: The Chemical Solvent Test (Lab Grade)

For 100% certainty without burning, factories use chemical solubility. This distinguishes Nylon 6 from Nylon 66 or Polyester.

- Formic Acid Test: Nylon will dissolve in concentrated Formic Acid. Polyester and PP will remain unaffected.

- Sulfuric Acid Test: Cotton dissolves quickly; Polyester dissolves slowly; Nylon dissolves eventually but behaves differently.

(Note: Handling these chemicals requires professional PPE and is recommended for lab environments only.)

Unsure About Your Material?

Don't guess with safety. Send your sample to the TMG Webbing Laboratory. We offer free material analysis for prospective B2B clients to ensure you get the exact specs you need.

Request Material AnalysisConclusion

Identifying your webbing material is the first step in quality control. Whether you need the buoyancy of Polypropylene for water rescue gear or the high abrasion resistance of Nylon for tactical belts, knowing the difference is vital.

At TMG Webbing, we guarantee the fiber content of every shipment. Contact us today for reliable manufacturing you can trust.