For pet product brands and manufacturers, selecting the right webbing isn't just about color—it's about tensile strength, abrasion resistance, and processing capabilities. A snapped leash or a frayed collar can damage a brand's reputation instantly. As a professional webbing manufacturer, TMG Webbing provides this technical guide to help B2B buyers choose between the three market leaders: Nylon, Polyester, and PVC Coated Webbing.

1. Nylon Webbing: The Premium Standard

Nylon (Polyamide) dominates the high-end pet market. It is known for its silky hand-feel and high tensile strength-to-weight ratio.

Key Manufacturing Characteristics:

- Shock Absorption: Nylon has a natural elasticity (stretch), which helps absorb the shock when a large dog lunges suddenly. This protects stitching points from failure.

- Dyeing Capabilities: Nylon is piece-dyed, allowing for deep, vibrant colors that penetrate the fiber. TMG can match specific Pantone C codes with high accuracy.

- Drawback: Nylon absorbs water (hydrophilic). If not treated, it can become heavy and prone to mildew if left damp.

Best For: Premium daily-use collars, leashes for large breeds, and products where "soft touch" is a selling point.

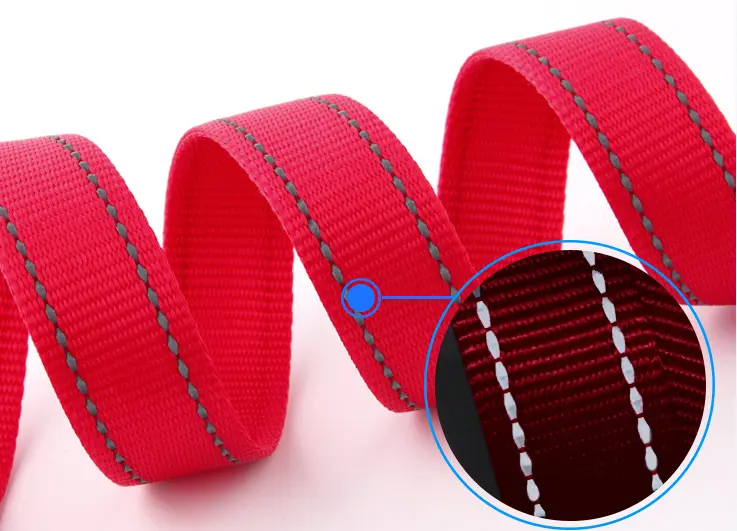

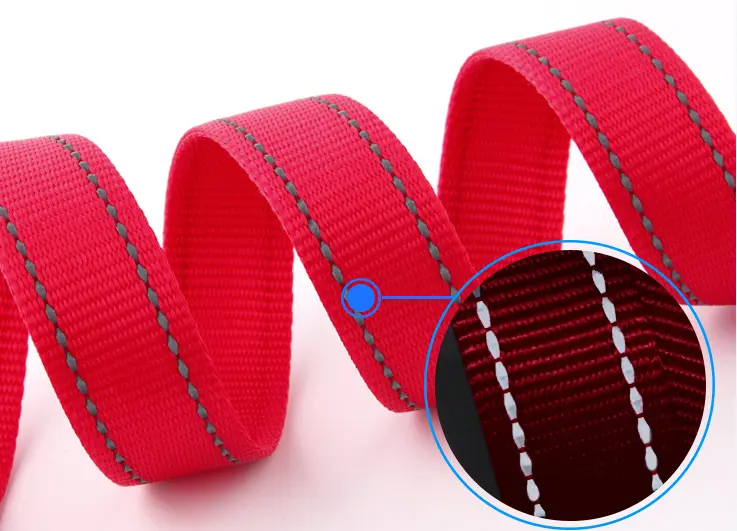

2. Polyester Webbing: The Customization King

While often cheaper than Nylon, Polyester is superior in specific technical applications, particularly for outdoor use and custom branding.

Why Manufacturers Choose Polyester:

- Sublimation Printing: This is the #1 reason to choose Polyester. It can withstand the high heat of dye-sublimation printing, allowing for complex, full-color patterns (logos, cartoons) that won't peel off. Nylon cannot be effectively heat-transferred.

- UV & Water Stability: Polyester is hydrophobic (repels water) and inherently UV resistant. It retains its break strength even after long-term sun exposure.

- Cost-Efficiency: Generally 20-30% more cost-effective than Nylon for bulk production.

Best For: Fashion-forward brands requiring custom patterns, outdoor adventure gear, and budget-friendly product lines.

3. PVC Coated Webbing: The Waterproof Evolution

Often referred to as "synthetic leather" or comparable to Biothane®, PVC coated webbing is a composite material featuring a high-tenacity polyester core with a thermoplastic coating.

Technical Advantages:

- Zero Maintenance: 100% waterproof, bacteria-resistant, and odor-proof. Mud and dirt wipe off instantly.

- Abrasion Resistance: The PVC coating protects the inner fibers from fraying against rocks or underbrush.

- Processing: Can be welded, laser-engraved, or embossed with leather-like textures.

Best For: Hunting dog collars, e-collars, waterproof long lines, and luxury "vegan leather" alternatives.

Technical Comparison: Specs at a Glance

| Feature | Nylon Webbing | Polyester Webbing | PVC Coated Webbing |

|---|---|---|---|

| Tensile Strength | High (Best for shock) | High (Static load) | Very High (Core dependent) |

| Water Absorption | High (Slow to dry) | Low (Fast drying) | Zero (Waterproof) |

| Printing Method | Screen Printing / Jacquard | Sublimation (Best) | Screen Print / Emboss |

| UV Resistance | Moderate | Excellent | Excellent |

| Hand Feel | Soft, Silky | Smooth, Firm | Flexible, Leather-like |

Safety Standards & Testing

At TMG Webbing, we don't just weave; we test. For pet products, we recommend specifying the following in your RFQ (Request for Quote):

- Break Strength Requirements: Standard 1-inch webbing should typically withstand 600lbs to 1000lbs+ depending on the dog breed target.

- Color Fastness: Ensure the webbing meets Grade 4+ for color fastness to prevent dye rubbing off on the pet's fur when wet.

Need Custom Pet Webbing?

Whether you need custom Pantone-matched Nylon or heat-transfer ready Polyester, TMG Manufacturing can provide samples and specs tailored to your brand.

Request Free SamplesReady to upgrade your supply chain? Explore our full range of webbing products or read more about Jacquard weaving techniques for premium branding.