In webbing procurement, a product spec sheet is the foundation, but it's far from the whole story. For brands that strive for excellence, true confidence comes from a supplier that goes "beyond the spec sheet" to establish a comprehensive quality control system from source to final product. This isn't just about performance; it's about protecting your brand's reputation and ensuring end-user safety. Today, we're pulling back the curtain on the TMG Webbing quality control system to show you how our commitment to quality is woven into every detail.

Step 1: Controlling the Source – Raw Material Inspection

It all starts with the yarn. Even the most advanced loom can't produce high-quality webbing from inferior yarn. That's why our quality control begins before the yarn even enters our factory doors.

- Supplier Audits: We partner exclusively with reputable, long-term yarn suppliers and conduct regular audits of their production capabilities and quality management systems.

- Batch Testing: Every arriving batch of yarn is subject to sample testing. We inspect its strength, denier, twist, and color consistency to ensure it meets our stringent internal standards—which are often higher than what our clients require.

Only raw materials that pass these rigorous inspections are approved and moved into our warehouse for production.

Step 2: In-Process Monitoring – Key Control Points in Weaving, Dyeing, and Finishing

Real-time monitoring during production is crucial for preventing widespread issues. We've established critical Quality Control Points (QCPs) at every stage.

- Weaving: Our technicians constantly monitor the looms, checking for consistent weave patterns, width, and thickness. They immediately identify and remove any webbing with defects like skipped threads, snags, or stains.

- Dyeing: We use a computerized color matching system to ensure a precise match with the client's Pantone codes. During dyeing, we strictly control temperature, time, and dye concentration to guarantee color stability and consistency across every batch.

- Finishing: Whether adding a functional coating for UV resistance, flame retardancy, or water repellency, we ensure the finish is applied evenly and then test it to verify its effectiveness meets specifications.

Step 3: The Final Gauntlet – Our Finished Product Testing Lab

Before any batch of webbing is packaged for shipment, it must pass a final series of tests in our in-house laboratory. Here, we use data, not just visual checks, to validate quality with specialized equipment.

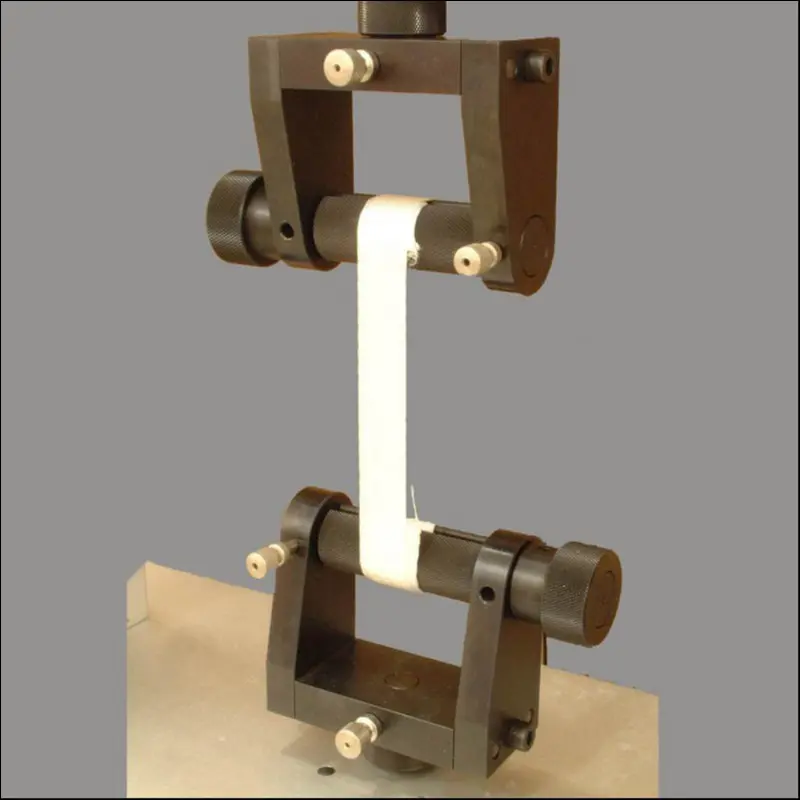

- Tensile Strength Testing: This is one of the most critical tests. Our tensile testing machine simulates the extreme loads the webbing will endure in its application, ensuring its breaking strength meets or exceeds the required specification.

- Colorfastness Testing: We conduct tests for colorfastness to washing, crocking (rubbing), and light to ensure the webbing won't fade or bleed, maintaining its appearance over time.

- Abrasion Resistance Testing: For products like backpack straps and safety harnesses, we use a Martindale abrasion tester to simulate wear and tear, assessing its long-term durability.

- Environmental Simulation: Upon request, we can perform UV aging and temperature cycling tests to ensure product performance and stability in harsh environmental conditions.

The True Value of Certifications: A Promise, Not Just Paper

For us, industry certifications like ISO 9001 and OEKO-TEX® STANDARD 100 are not marketing tools; they are a solemn promise to our clients.

- ISO 9001 certifies that we have an internationally standardized quality management process. This means our production is stable, traceable, and continuously improving, guaranteeing consistent order delivery.

- OEKO-TEX® STANDARD 100 assures you that our products are free from harmful substances and safe for human skin. This is non-negotiable for clients in the apparel, infant products, and medical industries.

Our Stance: Handling Occasional Quality Issues Responsibly

We know that no system is absolutely perfect. A factory's true character is revealed in its attitude and actions when a problem occurs. If a quality concern arises, our process is clear:

- Immediate Response: We engage with the client immediately, requesting detailed photos, videos, and descriptions of the issue.

- Trace & Analyze: Using the production lot number, we can quickly trace back to the relevant production records and raw material batches to conduct a Root Cause Analysis.

- Provide a Solution: Whether it involves a replacement, rework, or refund, we will propose a fair and reasonable solution and take full responsibility.

- Prevent Recurrence: We document the issue and update our operational procedures and QC standards to prevent it from happening again.

Choosing a supplier is choosing a quality partner. A quality control system that goes "beyond the spec sheet" is the strongest guarantee we can offer to protect your brand. Ready to work with a factory that genuinely cares about your product's quality? Contact us today to start your high-quality custom project.