In modern warfare, Night Vision Devices (NVGs) are standard equipment. For manufacturers of tactical vests, plate carriers, and helmet suspensions, this presents a critical challenge: standard webbing glows like a lightbulb under infrared light.

To ensure soldier safety, TMG Webbing produces IRR (Infrared Reflective) Camouflage Jacquard Webbing that meets strict military specifications. We adhere to standards like MIL-W-17337 and A-A-55301. Unlike cheap printed straps, our solution-dyed jacquard technology ensures the "invisibility" lasts through harsh combat environments.

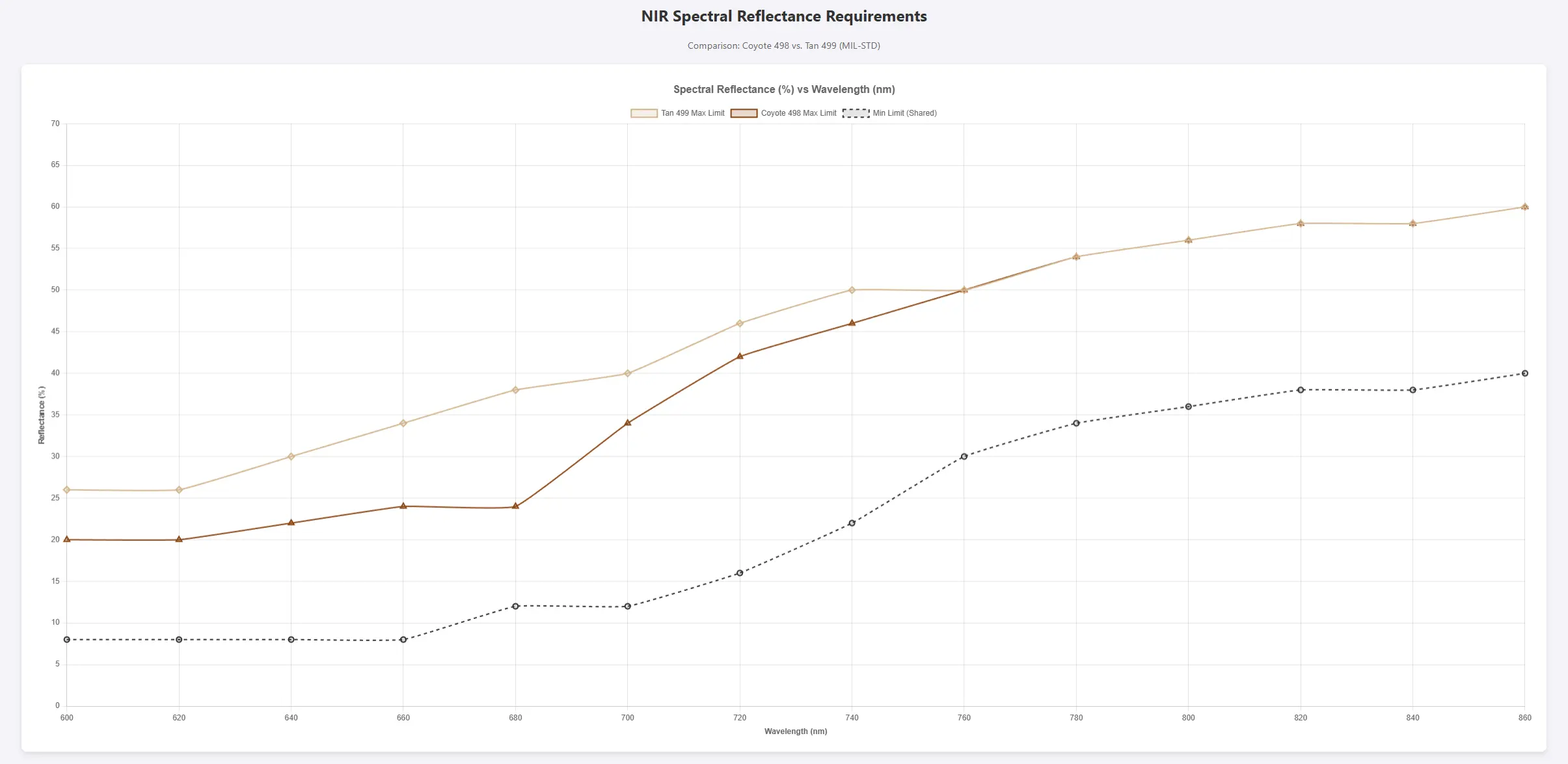

1. The Science of Silence: Spectral Reflectance Curves

True "Military-Grade" is defined by data, not marketing. The core requirement is the Near Infrared (NIR) Signature management across the 600nm to 1200nm spectrum.

If the webbing reflects too much light, the soldier is exposed. If it reflects too little (appearing as a black hole), they still stand out against natural foliage. At TMG, our rigorous Quality Control System guarantees specific reflectance values:

- Khaki/Tan 499: 48% - 58% Reflectance at 900nm.

- Ranger Green: Balanced to match woodland background noise (< 10% contrast).

- Black: Engineered low reflectance (not zero) to blend with shadows.

2. Jacquard vs. Printed: Why Process Matters

Many suppliers offer Camouflage Webbing that is simply white polyester printed with a pattern. This is acceptable for fashion, but dangerous for combat.

| Feature | TMG Jacquard (Solution Dyed Nylon) | Standard Printed Webbing |

|---|---|---|

| IRR Technology | Embedded in Yarn (Permanent) | Surface Coating (Washes off) |

| Abrasion Resistance | Pattern remains after 2000+ cycles | Pattern fades/turns white quickly |

| Wash Fastness | Grade 4-5 (ISO 105-C06) | Grade 2-3 (Fades rapidly) |

| Texture | Double-sided texture, non-slip | Single-sided, slippery |

Still debating between printing and weaving? Read our detailed comparison: Jacquard vs. Printed Webbing: A Guide to Custom Straps.

The "Dope Dyed" Advantage

We use Solution Dyed (Dope Dyed) Yarns. This means the pigment and IRR blockers are mixed into the molten nylon before it is extruded into fiber. Even if the webbing is cut, scraped, or exposed to UV for 100+ hours, the IR protection remains intrinsic to the material.

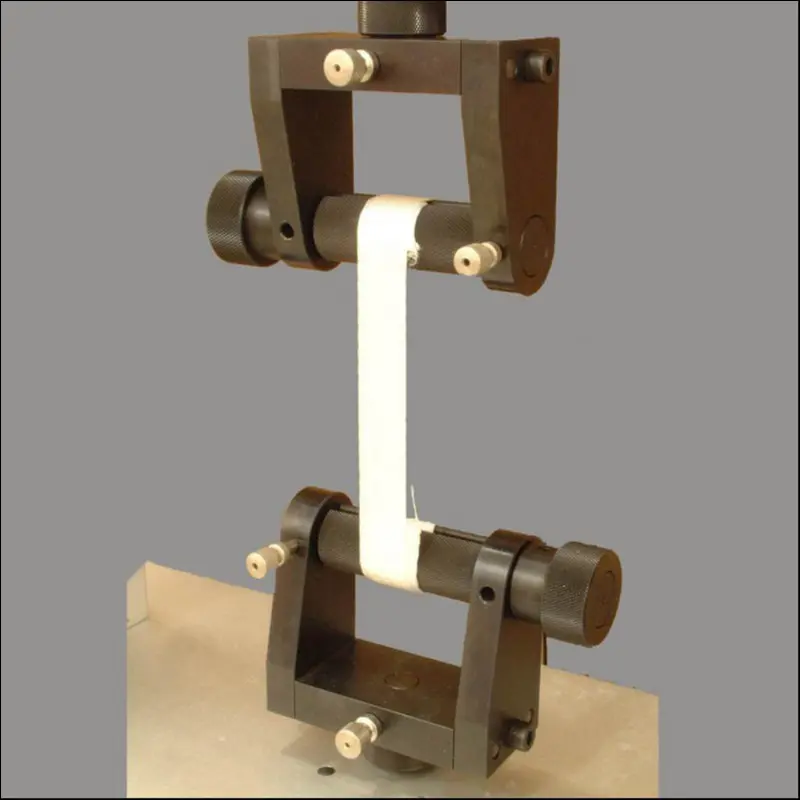

3. Engineering for Integration: Hardware & Sewing

A tactical vest is a system. Our webbing is engineered to work seamlessly with industry-standard Webbing Hardware & Buckles (like ITW Nexus or Duraflex) and automated sewing lines.

- Thickness Control: Maintained at tight tolerances (+/- 0.05mm) to ensure smooth gliding through buckles without jamming.

- Zero Carbonization: Our laser-cutting compatible weave ensures that hot-cutting does not result in hard, black burnt edges that irritate the skin.

- Tensile Strength: Exceeds 1200 lbs (544kg) for 1-inch Nylon Webbing, fully compliant with Class 3 safety requirements.

Verify Before You Manufacture

Don't rely on guesswork. We provide a full Spectral Reflectance Report with every batch of military webbing. Download a sample report or request a free test kit today.

Request IRR Test ReportYour equipment protects lives. Ensure your supply chain is solid. Explore our full range of Mil-Spec Webbing Solutions or contact TMG's Defense Material Engineers for a confidential consultation.