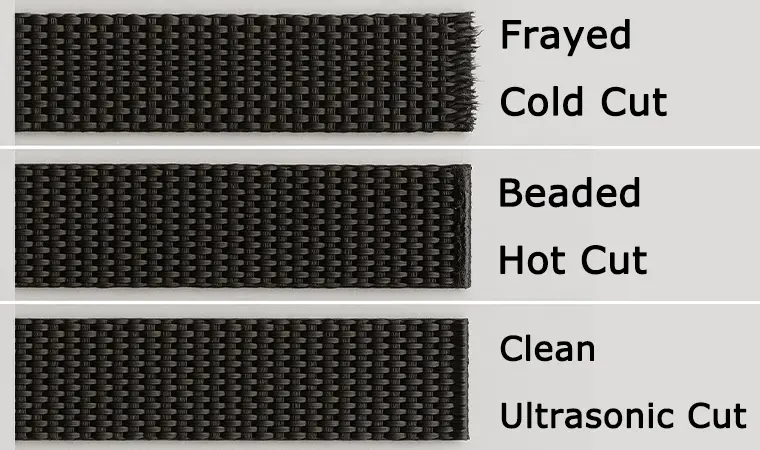

In product development, it's often the smallest details that separate a premium product from a mediocre one. For any item that uses webbing—from a military plate carrier to a high-end dog leash—the quality of the strap's cut edge is one of those critical, yet often overlooked, details. A frayed, messy edge doesn't just look unprofessional; it can compromise functionality and damage your brand's reputation.

As a webbing manufacturer, we understand that the cutting process is a vital final step in production. The chosen method impacts cost, efficiency, and the final quality of the component. This guide will walk you through the three primary cutting techniques—Cold, Hot, and Ultrasonic—to help you understand which is best for your product and why investing in a clean edge is essential.

Method 1: Cold Cutting (The Basic Approach)

Cold cutting is exactly what it sounds like: using a simple, unheated mechanical blade to slice through the webbing. It's the fastest and most straightforward method.

- Pros: Very low cost, extremely fast for bulk processing.

- Cons: On synthetic materials like Nylon and Polyester, it leaves a raw edge that will immediately begin to unravel and fray.

- Best For: Natural fibers like our Cotton Webbing, which don't melt and are less prone to fraying, or for prototyping where the edges will be immediately sewn into a seam.

Method 2: Hot Cutting / Thermal Sealing (The Industry Standard)

Hot cutting uses a heated blade that slices and melts the synthetic fibers simultaneously. As the blade passes through, the molten polymer fuses, creating a sealed edge that prevents fraying. This is the most common method for finishing synthetic webbing.

- Pros: Highly effective at preventing fraying, cost-effective for mass production.

- Cons: The process can leave a small, hard "bead" of melted plastic along the edge. This bead can be sharp or abrasive, making it unsuitable for applications that touch the skin. If not precisely controlled, it can also cause slight discoloration.

- Best For: Most general-purpose applications where durability is key, such as straps for backpacks and luggage, cargo tie-downs, and general outdoor gear.

Method 3: Ultrasonic Cutting (The Premium Solution)

Ultrasonic cutting uses high-frequency vibrations (typically 20-40 kHz) applied to a cutting tool, known as a sonotrode. The vibrations create intense, localized heat through friction, which cuts and seals the fabric from the inside out. There is no heated blade.

- Pros: Produces an exceptionally clean, soft, and perfectly sealed edge with no hard bead. The edge is smooth to the touch. It allows for precise cutting of complex shapes and holes.

- Cons: Higher equipment cost and a slightly slower process compared to hot cutting.

- Best For: High-end applications where user comfort and flawless aesthetics are non-negotiable. This includes medical devices, straps for baby products, premium pet harnesses, and mission-critical military & tactical gear where a snag-free edge is essential for passing through hardware.

Head-to-Head Comparison: Choosing Your Finish

| Feature | Cold Cutting | Hot Cutting | Ultrasonic Cutting |

|---|---|---|---|

| Edge Finish | Raw, Unsealed | Sealed, with a hard bead | Perfectly sealed, soft, and clean |

| Fraying (Synthetics) | Immediate | Prevented | Prevented |

| Suitable Materials | Natural fibers (Cotton), some synthetics for immediate sewing | Synthetics (Nylon, Polyester, PP) | Synthetics, especially thermoplastics |

| Edge Feel | Soft, but unravels | Hard, can be abrasive | Soft and smooth |

| Cost | Lowest | Moderate | Highest |

Why a Clean Edge is Mission-Critical for Your Brand

The danger of a poorly finished webbing edge goes far beyond looks. It poses direct risks to your product's performance and your brand's reputation.

- Functional Failure: A frayed end is a point of weakness. More importantly, it can snag, jam, or refuse to pass through adjusters, buckles, and other hardware. On safety harnesses or tactical vests, this isn't just an annoyance—it's a critical failure.

- Poor User Experience: The hard, sharp bead from a low-quality hot cut can chafe and irritate the skin. This is unacceptable for apparel, baby stroller harnesses, or pet collars where comfort is a key selling point.

- Negative Brand Perception: A fraying strap is one of the most visible signs of a cheaply made product. It tells your customer that corners were cut. As we detail in our guide to quality control, every component reflects on the final product. A perfect edge signals a commitment to quality that justifies a premium price.

The final cut on a piece of webbing is not an afterthought; it is a deliberate manufacturing choice. It reflects a brand's dedication to functionality, user safety, and overall quality. Whether your product requires a cost-effective thermal seal or the flawless finish of an ultrasonic edge, ensuring it's done right is fundamental.

At TMG Webbing, we have the expertise to not only supply the right material but also to advise on the best finishing methods for your specific application. We understand that every detail matters. Contact our team to discuss how we can provide perfectly finished webbing components for your production line.