Choosing the right webbing material, whether it’s high-strength nylon for dynamic loads or dimensionally stable polyester, is only the first step in creating a successful product. For many demanding applications, the performance limit of a webbing isn't defined by the yarn itself, but by a critical process: Finishing.

A finishing treatment, or post-treatment, uses physical or chemical methods to give webbing special properties that standard products lack. Think of it as specialized armor for a well-made strap, enabling it to withstand moisture, sun exposure, fire, and other extreme challenges. As veteran manufacturers, we know the right finish adds tremendous value and safety to your product.

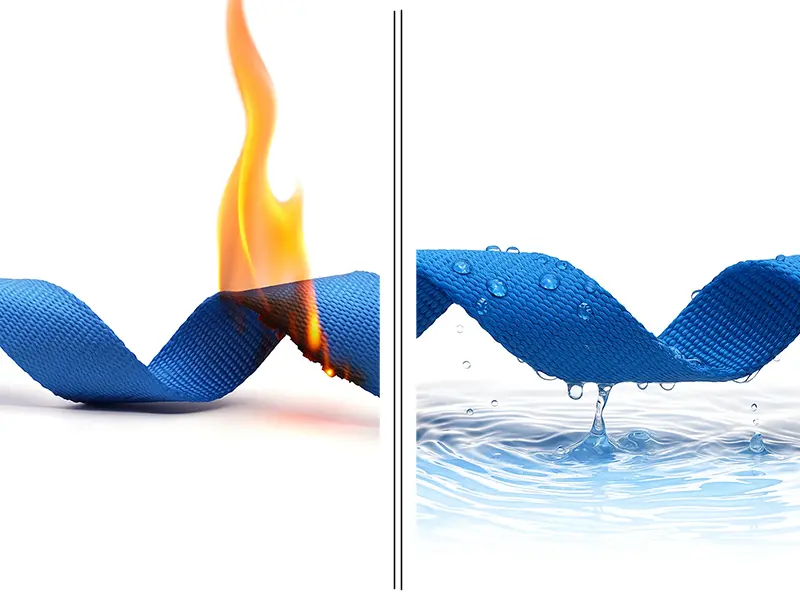

1. Waterproof & Water-Repellent Finishes

The Technology: This is achieved by coating the webbing with a hydrophobic chemical (like a fluorocarbon or silicone) or by laminating it with a waterproof membrane like PVC or TPU. This prevents water from penetrating the fibers.

Performance Gains:

- Prevents Strength Loss: Materials like nylon lose strength when wet; a waterproof treatment mitigates this.

- Resists Mildew & Rot: Inhibits the growth of mold in damp environments, extending the product’s lifespan.

- Stays Lightweight: Prevents the webbing from gaining weight by absorbing water, which is critical for outdoor gear.

Typical Applications: Marine and boating tie-downs, outdoor backpacks, pet leashes (especially PVC-coated styles), and tent straps. Even for inherently hydrophobic materials like Polyester Webbing, this finish can enhance its water-shedding performance.

2. Anti-UV (UV-Resistant) Treatment

The Technology: During the dyeing or finishing process, UV absorbers or blockers are added. These agents absorb or reflect harmful UVA and UVB radiation from the sun, protecting the webbing's polymer fibers from degradation.

Performance Gains:

- Slows Aging: Drastically reduces the embrittlement and strength loss caused by long-term sun exposure.

- Improves Color Fastness: Prevents colors from fading, keeping the product looking new for longer.

Typical Applications: Outdoor furniture, automotive seatbelts, cargo tie-downs, shade sails, and any safety equipment that is consistently exposed to sunlight. This is also crucial for products made from eco-friendly rPET materials, ensuring sustainability goes hand-in-hand with durability.

3. Flame Retardant (FR) Treatment

The Technology: The webbing is treated with special FR agents. When exposed to a flame, these chemicals activate to interrupt the chemical chain reaction of combustion, causing the webbing to self-extinguish once the flame source is removed.

Performance Gains: This is one of the most critical safety features, buying precious time for escape or rescue in the event of a fire.

Typical Applications:

- Firefighter safety harnesses and equipment.

- Racing and aerospace seatbelts.

- Personal Protective Equipment (PPE) for welding or other high-heat environments.

It's important to note that while high-performance fibers like KEVLAR® Aramid are inherently flame-retardant, applying an FR treatment to standard nylon or polyester offers a cost-effective way to add critical fire safety to specific products.

4. Other Specialized Finishing Treatments

Beyond the top three, we can engineer custom solutions for unique product needs:

- Anti-Static Finish: Incorporates conductive fibers or an anti-static agent to prevent static buildup, essential for electronics cleanrooms or fueling stations.

- Stiffening Finish: A resin treatment adds rigidity, making the webbing easier to thread through buckles or maintain its shape, as seen in military-spec MOLLE systems.

- Anti-Microbial Finish: Adds agents that inhibit the growth of bacteria, ideal for medical, hygiene, or sporting goods.

Conclusion: Choosing the Right Manufacturing Partner is Key

Webbing finishing is a precise science. An improper treatment can fail to deliver the desired performance or, even worse, compromise the webbing's original strength and durability. An experienced manufacturer provides:

- A deep understanding of materials and chemical agents.

- The expertise to balance multiple properties (e.g., achieving flame retardancy without making the webbing too stiff).

- Products that meet rigorous industry standards (e.g., NFPA, EN, FAR).

From basic polyester and nylon webbing to high-performance treated straps, we offer a one-stop solution from weaving to finishing. If your product faces unique environmental challenges, contact our technical team for a professional consultation and a competitive quote.