For B2B buyers and product designers, specifying the right webbing goes far beyond color and width. A critical question that directly impacts product safety, reliability, and brand reputation is: "How long will this webbing actually last in the field?" The answer is complex, but one of the most significant factors, especially for outdoor products, is its resistance to Ultraviolet (UV) radiation.

As a webbing manufacturer with over 20 years of experience, we've seen firsthand how sun exposure can degrade and destroy even the strongest materials. This guide provides our expert insights into webbing lifespan, focusing on the crucial role of UV resistance. Understanding these principles will empower you to make informed sourcing decisions that ensure your products stand the test of time.

What is UV Degradation and Why Does It Matter?

UV degradation, or photodegradation, is the process where sunlight, specifically UV radiation, breaks down the chemical bonds within a polymer. For synthetic webbing materials like nylon or polypropylene, this is a slow but relentless attack. Over time, this process leads to:

- Loss of Tensile Strength: The webbing becomes weaker and can no longer support its rated load, posing a significant safety risk.

- Brittleness and Cracking: The material loses its flexibility, becoming stiff and prone to cracking under stress.

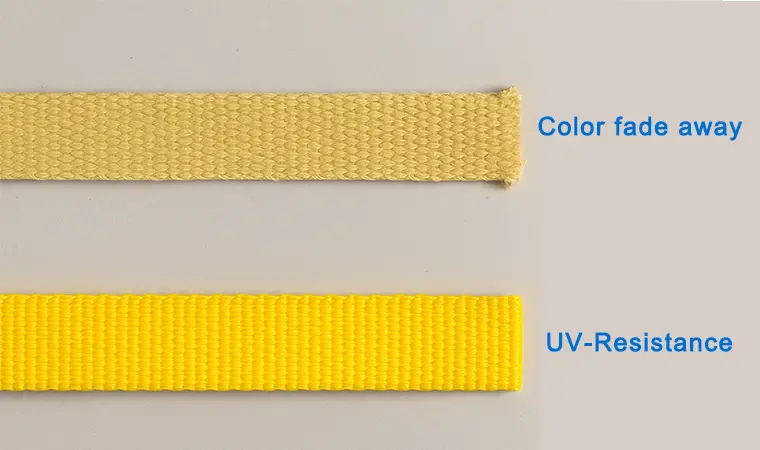

- Severe Fading: While often just a cosmetic issue, rapid color loss is a clear indicator that the polymer is being damaged by UV rays. For a deeper dive into this topic, see our in-depth guide to color fastness.

For any product used outdoors—from military & tactical gear to cargo tie-downs and pet leashes—choosing a material with poor UV resistance is a recipe for premature failure.

Material Showdown: Comparing UV Resistance in Common Webbing Fibers

The single most important decision you can make to maximize webbing lifespan in the sun is choosing the right material. Here’s how the most common options stack up.

| Material | UV Resistance | Abrasion Resistance | Best For |

|---|---|---|---|

| Polyester | Excellent | High | Outdoor, Marine, Cargo Control |

| Nylon | Fair (needs treatment) | Excellent | Pet Products, Tactical Gear |

| Polypropylene | Poor (needs stabilizer) | Low | Water Sports (floats), Light Utility |

1. Polyester (PES): The Outdoor Champion

UV Resistance: Excellent

When it comes to UV resistance, polyester is the undisputed king. It inherently withstands prolonged sun exposure with minimal loss of strength and color. This makes polyester webbing for outdoor use the default choice for applications like cargo straps, safety harnesses, tent guylines, and marine tie-downs. Its low water absorption and superior abrasion resistance further solidify its position as the top material for durable outdoor equipment.

If your product's primary function involves being outdoors, start with our range of Polyester Webbing.

2. Nylon (PA): Strong but Sun-Sensitive

UV Resistance: Poor to Fair

Nylon boasts incredible strength, a soft hand-feel, and excellent abrasion resistance, making it a favorite for products like pet collars and leashes. However, standard nylon has poor resistance to UV radiation. Without special treatment, the UV degradation of nylon straps can be significant, leading to a 50% strength loss in as little as 3-6 months of continuous sun exposure. For outdoor applications, it is crucial to specify nylon that has been treated with UV inhibitors during the manufacturing process.

Explore our versatile Nylon Webbing options and be sure to discuss UV treatment needs with our team.

3. Polypropylene (PP): The Budget Option with a Caveat

UV Resistance: Very Poor

Polypropylene is lightweight, floats on water, and is resistant to acids and alkalis, making it a cost-effective choice for many utility applications. Unfortunately, it has the worst UV resistance of the three. Un-treated polypropylene can become brittle and fail in a matter of weeks in direct sunlight. For any outdoor use, sourcing UV-stabilized polypropylene webbing is not just recommended; it's essential for product viability.

For applications where water resistance is key and UV exposure is limited or can be mitigated with additives, check out our Polypropylene Webbing.

Beyond the Fiber: Other Factors that Influence Webbing Lifespan

While material choice is paramount, other factors contribute to how well a strap holds up against the sun.

- Color: Darker colors, especially black, often perform better in UV tests. The carbon black pigment used in black dyes is an excellent UV blocker, helping to protect the polymer fibers within the webbing.

- Weave Density: A tighter, denser weave means the outer fibers provide more physical protection for the inner fibers, slowing the degradation process. This is a key difference between high-quality and low-quality webbing.

- Specialized Coatings: For maximum protection, Coated Webbing with a layer of TPU or PVC creates a physical barrier that completely shields the core fibers from UV, water, and abrasion. This is an ideal solution for high-wear, all-weather products.

As a manufacturer, we can apply various finishing treatments to enhance the performance and lifespan of any webbing product.

How to Source and Specify Long-Lasting, UV-Resistant Webbing

When discussing your needs with a manufacturer, being specific is key to getting a product that performs as expected. Here is a checklist for your next sourcing inquiry:

- Clearly Define the End-Use Environment: Will the product be used daily outdoors (e.g., on a boat), intermittently (e.g., a backpack), or primarily indoors?

- Specify the Material Based on UV Needs: For high-exposure applications, explicitly request "100% UV-resistant polyester webbing." If you need nylon for its feel, ask for "nylon webbing with UV inhibitors."

- Ask for Performance Data: A reputable manufacturer can provide data on how their materials perform in accelerated weathering tests (e.g., QUV testing), which simulate long-term sun exposure.

- Consider the Entire System: The webbing is only one part. Ensure stitching thread is also UV-resistant (polyester thread is a common choice) to prevent seams from failing before the webbing does.

For a complete overview of our material capabilities, browse our entire Products Page.

Partner with an Expert for Durable Webbing Solutions

The longevity of your product is a direct reflection of your brand's commitment to quality. Choosing the wrong webbing for an outdoor application can lead to safety hazards, negative reviews, and costly returns. By prioritizing UV resistance during the design and sourcing phase, you invest in the long-term success and reliability of your products.

Don't leave your product's lifespan to chance. Our team has the expertise to guide you to the perfect material and treatment combination for your specific environmental challenges.

Ready to source webbing that is built to last? Contact Us today to discuss your project requirements and get a quote from a trusted manufacturing partner.